Heavy Equipment Engine Rebuild Parts Inside the Machines That Keep the World Moving

Heavy Equipment Engine Rebuild Parts Inside the Machines That Keep the World Moving

Heavy Equipment Engine Rebuild Parts Inside the Machines That Keep the World Moving

“When heavy equipment stops breathing, rebuild parts are the lungs, heart, and bones that bring it back to life.”

Heavy equipment doesn’t ask for attention—it demands respect. From roaring excavators on mega construction sites to silent generators waiting for disaster response, engines are the beating heart of modern industry. And when those engines fail, heavy equipment engine rebuild parts step in as the unsung heroes.

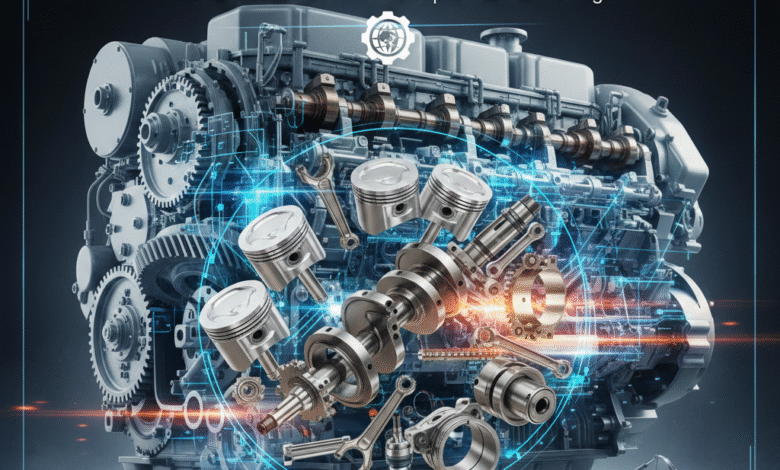

What Are Heavy Equipment Engine Rebuild Parts?

Heavy equipment engine rebuild parts are precision-engineered components used to restore worn or damaged engines to peak performance. Instead of replacing an entire engine (costly and wasteful), rebuilds extend life cycles and reduce downtime.

Common rebuild parts include:

-

Pistons & piston rings

-

Cylinder liners

-

Crankshafts

-

Camshafts

-

Main and rod bearings

-

Gaskets & seal kits

-

Fuel injectors

-

Oil and water pumps

Each part plays a role in restoring torque, fuel efficiency, and durability—especially critical in industries where minutes of downtime equal massive financial loss.

Why Engine Rebuilds Are Trending Right Now

The global heavy equipment market is shifting. Rising equipment costs, supply chain delays, and sustainability concerns are driving a rebuild-first mindset.

Key reasons rebuild parts are gaining traction:

-

Lower costs compared to full engine replacements

-

Reduced environmental impact

-

Faster turnaround times

-

OEM-quality aftermarket alternatives

OEM vs Aftermarket Rebuild Parts

Choosing rebuild parts is never a casual decision.

OEM Parts

-

Guaranteed fit and specifications

-

Higher price tag

-

Backed by manufacturer warranties

Aftermarket Parts

-

Competitive pricing

-

Often improved materials

-

Faster availability

“The best rebuild isn’t about brand loyalty—it’s about compatibility, metallurgy, and engineering discipline.”

Typical Engine Rebuild Checklist (Ordered)

-

Engine teardown and inspection

-

Block cleaning and crack testing

-

Cylinder re-boring or re-lining

-

Crankshaft grinding or replacement

-

Installation of rebuild parts

-

Precision torque and clearance checks

-

Final testing and break-in

Skipping even one step? That’s how engines fail twice.

Rebuilds as a Sustainability Statement

Rebuilding engines isn’t just mechanical—it’s philosophical.

-

Less scrap metal

-

Lower carbon footprint

-

Maximum utilization of resources

Common Machines That Rely on Engine Rebuild Parts

-

Excavators

-

Bulldozers

-

Loaders

-

Generators

-

Mining trucks

-

Agricultural tractors

Each machine has unique rebuild requirements, yet all share one truth: engines age, but they don’t have to die.